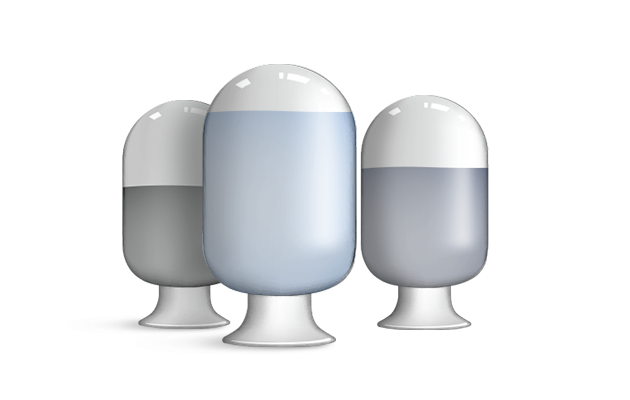

Product Introduction

Starem® Epoxy Molding Compound (EMC) is designed to encapsulate various delicate electronic devices. Starem® EMC features a broad line-up of halogen-free compounds to meet various customers’ needs and requirements.

Product Benefits

-

MUF EMC

Excellent assembly yield improvementCurable at low temperature

Void-less molding in fine pitch bump gap

Good gap filling characteristics with high flowability (Applicable for packages with fine pitch)Best productivityWide process windowSuperior releasing performance

Increase in throughput with high cleaning cycle -

PoP-t EMC

Best solution for Warpage control

Optimized technology for a variety of packages

Excellent yield improvementMaximizing customer’s productivity Wide process windowExcellent yield of lamination, improved reliability

-

Granule EMC

Excellent moldability with higher spreadabilityShort cure time for higher productivity

Enhancing filling characteristics

No wire sweep/sagging and chip sagging

Void-less molding in complex package configurationExcellent granule size controlWide process windowNo blocking and contamination