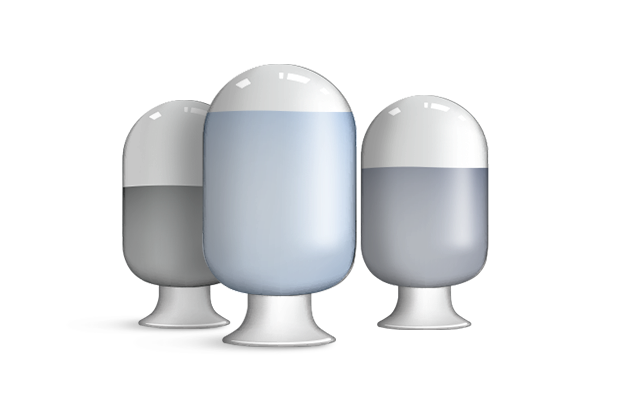

Product Introduction

SOH is an ancillary material to form micropatterns in the semiconductor. It requires high etching-resistance for it fills a gap to flatten the surface. SOH developed by SDI Material division is a material that is used for the new coating method in the patterning process of the semiconductor. It forms a thin film not by the existing method of *evaporation but by a new method of spin coating, which increases the accuracy of micropatterns. * evaporation process: evaporation is the method of thin-film fabrication. The source metal is heated to a high temperature to make it evaporated. And then the vapor particles travel directly to the target object (substrate) where they condense back to a solid state.

Product Benefits

The existing CVD (Chemical Vapor evaporation) process for forming a thin film is insufficient to meet the quality requirement for the micropatterns but causes high costs for its equipment. Samsung SDI’s SOH is a key material for the spin-coating process to form a membrane, which enables significant improvement of quality and productivity, as well as the cost reduction in equipment costs.

High affinity with the existing process materials

Ensuring consistent quality for 3 months at room temperature