TECHNOLOGY

Cathode Materials, the Source of a Strong and Long-lasting Battery!

ALL > Technology

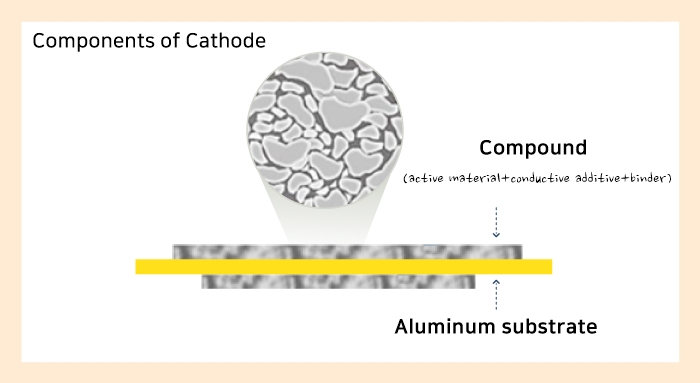

[ Components of Cathode ]

When we talk about features of a battery, ‘capacity’ and ‘power’ always come first. And a cathode is the material that decides capacity and power of a battery.

A cathode is composed of thin aluminum substrate, active material, conductive additive and binder. And ’compound’ includes active material, conductive additive and binder. We put a small amount of conductive additive into the active material which is composed of lithium oxide, and put the binder that holds material particles. The compounds are made of micro-particle powder form. If we apply these to both sides of aluminum substrate, that becomes a cathode material.

Active material decides the features of a cathode, and the number of electron changes depending on the active material, thus changing capacity and voltage of a battery. Numerous active materials can be created with lithium, oxygen and other materials. But there are only five cathode active materials that perform as a battery component.

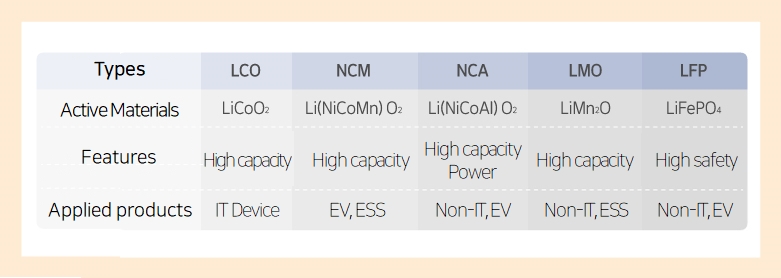

[ Types and pros/cons of cathode active materials ]

Cathode active materials are composed of lithium and metal. Active materials have different characteristics depending on type and ratio of metals. For example, Ni(Nickel) has high capacity, Mn(Manganese) and Co(Cobalt) has high safety and Al(Aluminum) increases power of a battery.

Samsung SDI Leads the EV market with ‘High-Ni’ Technology

NCA, NCM, LFP are the main cathode materials of an EV battery. And among these, High-Ni that has higher Ni(Nickel) is getting much attention to increase energy density of a battery.

If a battery has high density, it can be loaded with lighter weight and smaller size onto the electric vehicle. This is a crucial point, given that we should extend the ‘mileage’, the main challenge of an EV.

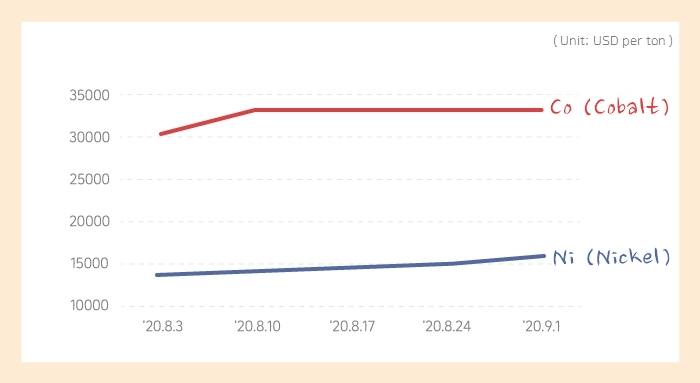

Moreover, as ‘High-Ni’ cathode materials with over 80% of Nickel are cost competitive, they can replace Co(Cobalt) that is expensive with high price volatility.

[ Price of Nickel and Cobalt over the last month (Source: The London Metal Exchange) ]

Battery companies now focus on developing NCM, but Samsung SDI is developing NCA and NCM cathode materials. In particular, it is more difficult to develop NCA than NCM since it is hard to compose raw materials and control moisture.

NCA has higher power and energy density than other materials such as NCM, LMO. So, it is often used at power tools in the small battery market. Samsung SDI is dominating the small battery market with a high market share thanks to our high NCA technology.

NCA materials based on Samsung SDI’s technology provide higher power and safety than other cathode materials.

With our exceptional NCA technology, we applied High-Ni cathode materials with over 88% of nickel to power tool cylindrical batteries in 2015, showing its great performance and production technology. And High-Ni NCA cathode materials with 88% of nickel are applied to the next-generation Gen.5 EV battery.

Samsung SDI will go one step ahead by developing safer High-Ni NCA cathode materials that contain higher content of Nickel to further increase energy density of a Li-ion battery.